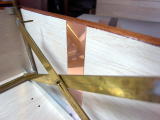

I cut a screw in the brass line for arm connections

On showing it

I reproduced the mechanism that I made with a toy more than 40 ago and

announced it as a mechanism layout in 2005.

The fabric is not changed from the first, but newly-designed, the operation

stability of the mechanism, the mechanism durability improve.

I felt fine without shafts appearing outside the mechanism box and watched

it.

Placed a production process in our HP at the time of announcement in detail in 2005,; but is BR from neighboring people and model friends

When it should make a secret, I received an opinion and came with an exhibition near at hand when "so".

However, when the better method comes out to opening in what I do without

the need to hide particularly including production technique and such a

mechanism structure whenever I repeat age, I did it in the thing that Japan

may be put an inquiry to than the cause a lot again from the foreign countries

and it is the past work, but shows the VCR which I saved as a production

record at this time.

Works are 1 / 87 HO narrow gauge of the 2010 work. The Saturday river railroad It is w400xd300xh205mm (a box outer size and a projection are not included).

Present (June 5, 2012)

A new work article is under work in parallel to photography that introduction of the details from a design and a work process to completion should be carried out by a photograph and video.

Since I am making in parallel to other works, completion becomes slow a little from a schedule.

Public presentation with a publication may become first according to a situation.

Production of a box and the mechanism I added it on Oct.14, 2012

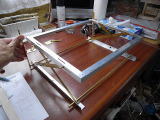

It is the constitution parts of the mechanism department.

It is a frame to put a layout on (it fixes) that it is square and is crossed

As for the silver color, aluminum, the others are brass.

I attach metal fittings over the front part of BOX and am completion

I founded an anti-rolling adjuster of the frame

I put a copper sheet to make sliding better

It is in condition to have assembled all parts

If I check movement and do not have any problem

I fix it in a box

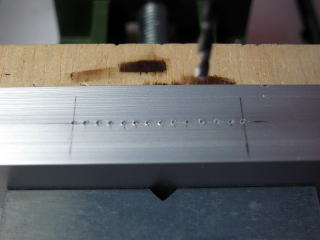

Installation hole of the connection arm

I fix it with a pipe fixture to open out in two places of right and left direction

Slit

Because if there is a fraise table, it is easy, but does not have

... which I used the file for is that is worn-out that it take time and opens it by such a method.

Because it is dangerous, I cannot recommend it, but am early comfort.

But, please go by a self-responsibility when you are considered to be it like

in very dangerous one

Installation preparations for mechanism stopper

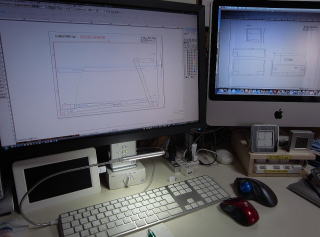

I design it by CAD softwareware.

I design the track placement by CAD softwareware.

Operation VTR of a mechanism mechanism

I attach a hinge, and the BOX part is completed for the time being.

I make a box.

I have you cut designated dimensions in a home center, but cannot expect the accuracy by the millimeters unit.

Put materials together and I adjust it and finish it tight and assemble it.

Installation of a shaft and the arm

I let a shaft adhere to anti-skidding of the arm and solder it

I fix a layout to the frame

I draw the sky inside of a cover.

The painting of the BOX outside

I finished it with teak-colored varnish this time.

I make a hole for panel installation through the front part to incorporate power pack.

The assembling of the box uses a bamboo nail.